#Rotary encoder

Explore tagged Tumblr posts

Text

How Can You Benefit from Using a Hollow Shaft Rotary Encoder in Automation

Discover how hollow shaft rotary encoders simplify installation, save space, and boost automation efficiency across industries like textile, packaging, and hoisting.

0 notes

Text

UNBREAKABLE BOND: Sonic and Tails themed linking fighsticks

-features the S2 DRIVE, an Allfightsticks 9.5" SEGA 2P mini arcade stick, alongside the mi2con (aka miNIcon), an even smaller arcade stick built inside a project box

-S2 Drive features a Seimitsu lever and buttons, and the mi2con has a rotary encoder for playing arcade games with rotary joysticks or spinners

-ethernet ports on the sides allow the mi2con to connect to the S2 Drive, allowing it to be used to add extra controls for training mode, or right stick and camera controls

1 note

·

View note

Text

Jayashree Encoders provides ip65 rotary encoder, photoelectric rotary encoder, rotary encoder 1024, rotary encoder 600 pulse, rotary encoder pins at best price. It is the best rotary encoder Supplier, Manufacturer, Exporter, Dealer company in Pune.

0 notes

Text

Explore the world of miniature rotary encoders, where precision meets compact design. Learn how these versatile devices provide accurate rotational sensing for a wide range of applications. Find out more about the benefits and uses of miniature rotary encoders today.

1 note

·

View note

Text

Permanent Magnet MEASUREMENT AND ANALYSIS SERVICES

Permanent Magnet MEASUREMENT AND ANALYSIS SERVICES Entrust your magnet samples to our expert team to measure and analyze magnetic fields using HSMAG’s advanced measurement systems. FROM HIGH ACCURACY MEASUREMENT TO COMPREHENSIVE ANALYSIS As the most proficient users of our measurement systems, our own applications engineering team has tremendous experience in performing precise analyses and…

#DIPOLE POSITION SENSOR MAGNETS#Handling Systems#LINEAR ENCODER STRIP MAGNETS#Linear measurement#Linear scales#Linear sensing heads#Magnet Assemblies#magnet testing#MAGNETIC field#Magnetic Measurement Solutions#Magnetic Solution#Measuring Magnets#Permanent Magnet Assemblies#PERMANENT MAGNET ROTOR ASSEMBLIES#Robotics#ROTARY ENCODER MAGNETS#Rotary Measurement#Rotary scales#Rotary sensing heads#sensor magnets

0 notes

Text

Precision Rotation Tables - Velmex Inc

Precision Rotation Tables: Enhancing Accuracy in Motion Control

Precision rotation tables, also known as rotary tables or indexing tables, are essential components in various industrial and scientific applications. They are designed to provide precise angular positioning, enabling accurate control over rotational movements in manufacturing, research, and automation systems.

What Are Precision Rotation Tables?

Precision rotation tables are mechanical devices that allow for controlled rotation around a single axis. They can be manually operated or motorized, depending on the level of precision required. These tables are commonly used in CNC machining, metrology, robotics, and optical applications where exact angular positioning is critical.

Key Features and Benefits

High Accuracy and Repeatability: Precision rotation tables are engineered to achieve tight tolerances, often within arc-seconds, ensuring consistent and repeatable positioning.

Load Capacity: They can support various load sizes, from lightweight optical components to heavy industrial machinery, without compromising accuracy.

Versatility: Available in different configurations, such as worm gear, direct drive, and air-bearing tables, they cater to diverse applications requiring different levels of precision and speed.

Integration with Automation Systems: Modern precision rotation tables can be easily integrated with computer-controlled systems, enhancing efficiency in automated processes.

Applications of Precision Rotation Tables

CNC Machining: For precise cutting, drilling, and milling operations, allowing complex geometries and multi-axis machining.

Metrology: In coordinate measuring machines (CMMs) for accurate measurement of angles and dimensions.

Robotics: For the precise movement and positioning of robotic arms in assembly lines.

Optics and Photonics: In laser systems and telescopes where fine angular adjustments are crucial.

Choosing the Right Precision Rotation Table

When selecting a precision rotation table, consider factors such as load capacity, rotational speed, accuracy requirements, and environmental conditions. Motorized tables offer higher precision and automation capabilities, while manual tables are suitable for simpler tasks.

Conclusion

Precision rotation tables are indispensable tools in industries that demand high levels of accuracy and control. By enabling precise angular positioning, they contribute significantly to the efficiency, quality, and innovation of modern technological processes.

#lead screws#xy table stepper motor#inductive rotary encoders#national petrographic#joystick motor control#rotary table controller#motorized positioning tables#motorized xy system#measuring counters

0 notes

Text

the phrase "steadily increasing volume" suggests to me one of those super-stepdown youtube clickbait gearboxes hooked up to turn a volume knob very verrrrrry slowly clockwise

and then probably break something when it reaches full volume because the torque stepup would just rip through the knob stop

1 note

·

View note

Text

Rotary Encoder Market: Global Demand Analysis & Opportunity Outlook 2036

Research Nester’s recent market research analysis on “Rotary Encoder Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitor’s analysis and a detailed overview of the global rotary encoder market in terms of market segmentation by type, product, application, end-user industry, and by region.

Increasing Industrialization and Digitization to Promote Global Market Share of Rotary Encoder

The market is predicted to increase moderately as a result of the Industry 4.0 revolution and digitization, which have further expedited the adoption of automation across a number of industries. Industry 4.0 persuaded OEMs to include IoT in their operations due to the consistent increase in IoT usage and digital transformation occurring across several industries. For instance, according to the International Data Corporation's (IDC) Worldwide Semiannual Internet of Things Expenditure Guide, European investment in the Internet of Things (IoT) exceeded USD 202 billion in 2021. It is expected to increase by double digits through 2025.

Request Report Sample@

In addition to these, Governments everywhere are promoting the adoption of various automation technologies to support the structural expansion of industrial firms. Governments across the globe focus on the manufacturing sectors since they are essential to this progress. This is expected to promote market expansion overall by increasing the usage of industrial robots.

Some of the major growth factors and challenges that are associated with the growth of the global rotary encoder market are:

Growth Drivers:

Surge in Technological Developments and High Accuracy Could Strengthen Market Growth

Rising Automotive Industry

Challenges:

Lack of product differentiation is one factor hindering the growth of the rotary encoder market. Because rotary encoders are used in such large quantities in the electronics, aerospace, automotive, and other industries, customers purchase them in bulk. Rotary encoders can have a wide range of functions and applications. Due to the wide variety of huge enterprises offering similar technology items, consumers have many options. In order to compete with larger manufacturers for the high volume of these products, manufacturers are under pressure to reduce their pricing. This is troublesome because it puts pressure on manufacturing prices. Encoders encounter a number of issues and constraints that reduce their capacity to endure competition because of their few brittle parts and possible complexity and potential error causes that could lead to the inaccuracy are some of the major factors anticipated to hamper the global market size of rotary encoder.

By application, the global rotary encoder market is segmented into metal forming & fabrication, servo motor, elevator industry, machine tool and material handling. The machine tool segment is to garner the highest revenue by the end of 2036 by growing at a significant CAGR over the forecast period. In machine tool applications, rotary encoders are used to accomplish precise sensing and positioning. A machine can determine the exact commutation angle and axis alignment. Rotating encoders improve system precision and enable optimal machine performance. It is heavily used in this application for these reasons. It is anticipated that the robust adoption rate and increasing demand will drive the robotics segment's notable expansion. The International Federation of Robotics (IFR) projects that between 2020 and 2022, factories globally will deploy close to 2 million industrial robots. These factors should boost demand for rotary encoders because of their widespread application in robotics.

By region, the Europe rotary encoder market is to generate the highest revenue by the end of 2036. Industrial robotic applications are one of the many potential markets for encoders, and this increase is projected to boost the market growth in the region. Automation in many industries in Europe may eventually lead to a rise in the need for robots, which will also raise the need for rotary angle sensors. Another dynamic area that has a lot of promise for the increase in encoder demand over the course of the projection period is the electronic sector.

Access our detailed report at:

0 notes

Text

Pepperl+Fuchs FVM58 ABSOLUTE ROTARY ENCODER

Manufacturer: Pepperl+Fuchs Product no. : FVM58N-011AEA3GN-0813 Product type : Multiturn absolute encoder Data format : F = Fast parallel Shaft version : V = Solid shaft Principle of operation : M = Multiturn Housing material : N = Aluminium, powder coated Shaft dimension/flange version : 011 = Shaft ÿ10 mm x 20 mm with clamping flange Connection type : AE = Plug connector type 9426,…

View On WordPress

#Absolute Rotary Encoder;#P+F बैरियर#P+F ปัญหาและอุปสรรค#P+F halangan#P+F hambatan#P+F rào cản#P+F الحواجز#Pepperl+Fuchs Absolute Rotary Encoder;#Pepperl+Fuchs Barriers#pepperl+fuchs encoder#pepperl+fuchs sensor

0 notes

Text

Leftovers & layout - WLED board revision A completed!

Sunday night, Babyada went to bed early, so we finished the capture and layout of our WLED board. Thanks to all the suggestions, we were able to implement quite a few!

For power, use USB C PD with switch-select or DC up to 24V; they are diode-OR'd together with PMEG3050

https://www.digikey.com/short/zv22b0pq

into a massive 5A 24V fuse

https://www.digikey.com/short/43qwwtwm

For the 5V regulator, we picked NCP718ASN500T1G

https://www.digikey.com/short/bb9ncc0n

- it's linear, but we don't need a lot of current at 5V. For 3.3V, we went with our trusty TPS54202

https://www.digikey.com/short/c1wnnf94

Upon request, we kept the ICS-43434 I2S microphone

https://www.digikey.com/short/28zwrrhz

and added an IR 38KHz receiver. For external connectivity, there's an ADC/DAC/GPIO #27 breakout on a JST SH 3-pin and I2C on a StemmaQT/Qwiic 4-pin.

We also added a 2x3 breakout header with 3V, GND, and 3 more GPIO so you could connect an external microphone, IR receiver, buttons, or rotary encoder. The terminal blocks have three 5V level-shifted outputs with 100 ohm in-line resistors and power/ground pairs for each. If you need just one more LED strand, the fourth 5V signal is on the 2x3 block.

Rounding out the design are four mounting holes, a reset button, GPIO #0 user button, GPIO LED, and an individual NeoPixel, which could be useful for testing. It's still pretty small, 2" x 1.3". With an ESP32-Mini module, we can pick a PCB or wFL antenna port, and it's an easy swap to make it use an ESP32-Pico, which has 2MB PSRAM.

Whatcha think - anything else we should add or watch out for?

#wled#esp32#electronics#pcbdesign#electronicsproject#makerlife#hardwarehacking#openhardware#diytech#electronicsengineering#usbc#miccontroller#neopixel#iotdevices#irreceiver#powersupplydesign#smalldesign#esp32mini#hardwarelayout#buildprogress#techinnovation

41 notes

·

View notes

Text

Explosion proof Absolute Rotary Encoder with RS232 Modbus RTU Communication

Key features

Power-Off Memory: Maintains precise position data even during power outages, eliminating recalibration needs and ensuring consistent performance.

Absolute Multi-Turn Capability: Delivers accurate position data across numerous turns, making it suitable for intricate rotational tasks.

Mechanical Gear Counting: Uses sturdy mechanical gears for turn counting, eliminating the dependency on internal batteries and boosting reliability.

High Resolution: Offers up to 17-bit resolution with 0.07° accuracy for meticulous angle measurements.

Compact and Rugged Design: Features a minimal outer diameter of just 39mm and EX protection, making it resilient in harsh environments.

Data Interfaces: Equipped with RS232 connections and supports Modbus RTU, enabling seamless data integration and communication.

Visit https://briterencoder.com/product/explosionproof-absolute-rotary-encoder-with-rs232-modbus-rtu-communication/ for more.

0 notes

Text

Enterprise (1984) by David Woodfield, UK. Enterprise won the European Micromouse competition in 1984 and 1985 and the UK competition in 1986.

"At last in Copenhagen, at Euromicro 1984, Britain won the title back in the shape of 'Enterprise', grandson of Thumper. The shortest path was seventy squares in length, covered in an amazing twenty-seven seconds. David Woodfield (Enterprise) and Alan Dibley (Thezeus-5) won travel prizes donated by the Japan Science Foundation to join teams from Finland and Germany in the Japanese 'All World' contest in Tsukuba, held in August 1985." – Alternative Robotics: Robat and Micromouse – the Cybernetic Challenge, by Professor John Billingsley, Practical Electronics, July 1986.

At the 1985 World Micromouse Contest held in Tsukuba '85, Japan, Enterprise gained 7th place (40.91 secs) and also won the 'Science and Technology Museum Award'. "The award was given in particular for the hardware aspects. It is a lightweight three-wheeled mouse weighing 580g. Both the two driving wheels and the steering wheel are DC motors, and the steering wheel is directly connected to a rotary encoder." – Mouse: Journal of the Japan Micromouse Association, September 1985.

"A CMOS processor, the NSC800, provides the brain power along with 2k EPROM and 2k RAM. The NSC800 is based upon the Z80 processor. Dave was not impressed with this processor due to a buggy instruction set. Development was, however, made easier by the ready availability at that time of a Sharp microcomputer based on the Z80. Wall sensing is achieved by means of seven top-down reflective IR sensors, three on each side and one out front. these sensors are pulsed for about 25us every 1.25mm of forward travel. The pulsing is triggered by the front wheel mounted odometry sensor. Sensor outputs are AC coupled and high-pass filtered before being captured 20us after the pulse start. Energy is provided by 1/2AA NiCd cells giving a typical running time of 30 minutes. The drive train uses two motors with separate control circuits for each. D/A convertors provide analogue signals to set the motor speed." – Pete Harrison.

In 2001, Enterprise appeared in Techno Games, a British TV series that ran from 2000 to 2003. "It performed spectacularly well, winning the whole competition as well beating its opponent. … It shot out of the starting position in rapid time and never went straight into a dead end. Flawlessly, Enterprise darted around the maze into the centre at the incredibly quick time of 15.03 seconds, taking the Gold Medal. … For unknown reasons the round "head" of Enterprise is removed during its run." – Enterprise, Techno Games Wiki.

The video is an excerpt from "The first World Micromouse Contest in Tsubuka, Japan, August 1985 [2/2]."

10 notes

·

View notes

Text

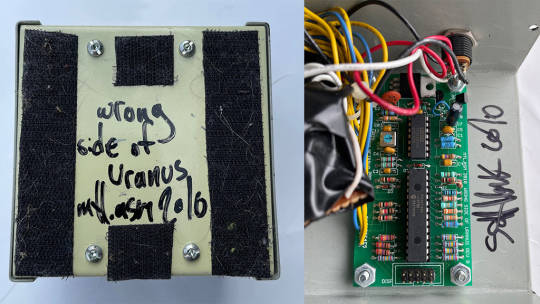

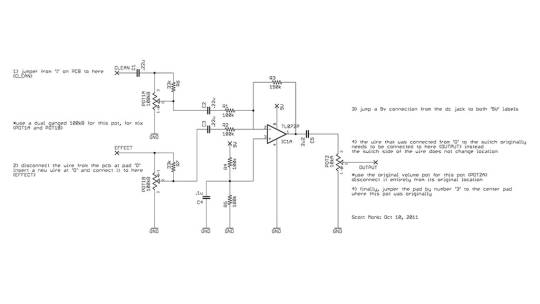

Montreal Assembly - Worng Side Of Uranus

"If you’re a regular Cabinet peruser, you’ve joined me as I waxed nostalgic for time periods I’ve never lived in, you’ve noticed me orating some company and component history, and you’ve almost certainly seen me talk about the best effects in their respective classes. And while there are plenty of classes and there is certainly enough love to go around, today I present you with my favorite pedal of all time: the Montreal Assembly Wrong Side of Uranus.

While many of you know Scott Monk and his amazing company for the Count to 5, he’s been in business for much longer than you think, and he’s made more things than most people know about. I first found out about him in 2009 while chasing wares by one of pedal history’s most sought-after builders, Etienne Blythe of Sonic Crayon.

If you were as into pedals as I was in the late-aughts… well, there’s a chance you still may never have heard of Sonic Crayon. However, at one time, Sonic Crayon’s wares were in extreme demand, with resellers ransacking the limited inventory and flipping the pedals for four times the price. His most famous may have been the Hollow Earth. His most unobtainable may have been the Anti-Nautilus. The one I wanted was the Moth.

The Moth was Sonic Crayon’s bitcrusher, and back in 2008 and 2009, that wasn’t an effect you could get just anywhere. However, Sonic Crayon had an old-school way of doing things: When he felt like making a batch, he did. Then he put 10 or so up for sale on his blog, and by word of mouth they’d sell out in minutes. One time, when checking his blog for a potential drop, I saw a new post where he said that if you’re tired of waiting for a Moth, there’s another Canadian guy making bitcrushers and that his were admittedly better. Who am I to argue? Let’s go.

That company was Montreal Assembly. At that time, Scott had only released two pedals, the Uranus and another insane device called Probability of a Fax Machine. When I heard the crude “basement demos,” I was sold. The problem: the sales tactics were exactly the same as Sonic Crayon—made and sold whenever. I never caught one. But my friend did.

My friend had gone off to college and left a present for me. I took a train and met their dad at a station in the suburbs, retrieved the box and opened it right there on the train. The Uranus was inside. When I got home I plugged everything I could into it. I messaged its creator, Scott, on Gmail Chat and geeked out when he answered.

I asked him if it was possible to add a mix circuit to the Uranus and Scott took time out of studying for signal processing exams to draw me up a somewhat complicated add-on schematic. Being somewhat intermediate with prototyping board, I hadn’t done a whole lot of my own stripboard layouts. Be that as it may, I cobbled it together. It worked. Now, I could blend the clean signal in with the bitcrushed one.

Despite being housed in a spray painted computer project box and featuring a barren aesthetic landscape, the Uranus is an impeccably engineered piece of sonic kit. Like most bitcrushers, there are knobs for bit rate and sample rate reduction. The third is volume. However, the bit rate knob is a pushbutton rotary encoder; as you turn it, it displays the bitrate in the seven-segment display. When the pedal is in bypass, the display flashes “bypass,” one letter at a time. Pressing down on the rotary encoder cycles through a slew of modes—ten to be exact—called things like “Dialup,” “Hostile” and more, including an incredible bitcrushed trem called “Blipo'' and a modulated sample rate mode called “Plunger.” It’s total labor-of-love stuff and I am here for it.

Mine is labeled 2010 and is one of a handful known to exist, and the only one with this mix knob. You may have seen one in a promotional photo that Strymon posted of its El Capistan being used in the studio by Godspeed! You Black Emperor, with the Uranus riding sidesaddle. Many, many people have never heard of it, and some of you may have never heard of Montreal Assembly before now. I urge you to change that.

At NAMM 2020, I actually saw Scott walking by our booth and I recognized him from some old demos. I ran down the aisle and tapped him on the shoulder. He looked right at me, then read my name badge, looked back up and said “Heyyy, Kula, how’s that bitcrusher treating you?” What a legend."

cred: catalinbread.com/blogs/kulas-cabinet/montreal-assembly-wrong-side-of-uranus

22 notes

·

View notes

Text

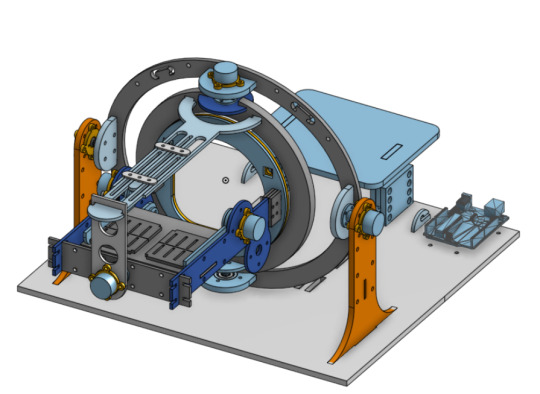

Re-designing my Waldo

I found out they make rotary hall effect sensors (why did no one tell me). These little guys are miracles; they have the exact same effect on the voltage as a traditional potentiometer but with all the advantages of hall-effects. Straight upgrade. And unlike optical encoders, the positioning is absolute, so no calibration needed. The sensors are a slightly different form factor though, and because my first prototype prioritized fewer parts over upgradeability, a tiny little change requires a complete re-design. As you can see, I'm trying to avoid that in the future. This version has far more parts that bolt together rather than weld, particularly where sensors get installed. This was also an opportunity to make some long overdue ergonomic adjustments (the thumb position was atrocious) and add a couple extra sensors for my fingers. If I've done everything right (and I almost never do) this will be easier to repair, lighter, and more expressive.

9 notes

·

View notes

Text

Permanent Magnet Rotor Inspection Solutions

Permanent Magnet Rotor Inspection Solutions As a technology leader in permanent magnet inspection, HSMAG provides a complete solution to measure, visualize and analyze magnetic field distributions of different types of permanent magnet rotors. A Complete Solution for Permanent Magnet Rotor Inspection HSMAG ‘s hardware and software work harmoniously to derive important characteristics of permanent…

#DIPOLE POSITION SENSOR MAGNETS#Handling Systems#LINEAR ENCODER STRIP MAGNETS#Linear measurement#Linear scales#Linear sensing heads#Magnet Assemblies#magnet testing#MAGNETIC field#Magnetic Measurement Solutions#Magnetic Solution#Measuring Magnets#Permanent Magnet Assemblies#PERMANENT MAGNET ROTOR ASSEMBLIES#Robotics#ROTARY ENCODER MAGNETS#Rotary Measurement#Rotary scales#Rotary sensing heads#sensor magnets

0 notes

Text

Call me a rotary encoder the way I can be spun around freely with no hard limits

#tactile input#electronic components#robot girl#switch#overstimulated circuits#t4t#free use robot girl#stim with my knobs

2 notes

·

View notes